👋 Hello Amigos! Dr. Molina here 👨🔧

Last week, the APEC conference took place, bringing together top experts in Power Electronics. It is a conference with strong academic weight but also features a highly relevant industry exhibition. One of my favorite parts is the educational seminars.

This year, for the first time, there was a seminar on AI in Power Electronics, in addition to an industrial session dedicated exclusively to the topic (SESSION IS10: AI Tools for More Efficient Power Electronics Design).

It has taken many attempts, but it seems that this time, AI is here to stay at APEC. That article I wrote in 2019 on this topic for Bodo Power now feels like a distant memory (Follow me on LinkedIn, I’ll post it).

The difference between 2019 and 2025 is the LLMs, which have come to turn everything upside down.

To differentiate the use of AI in Power Electronics, let's divide it into two categories:

AI models for specific cases, trained with proprietary data. For example, a fuzzy logic regulator trained with AI or the foil loss model we use at Frenetic.

The use of general models, such as LLMs, in Power Electronics.

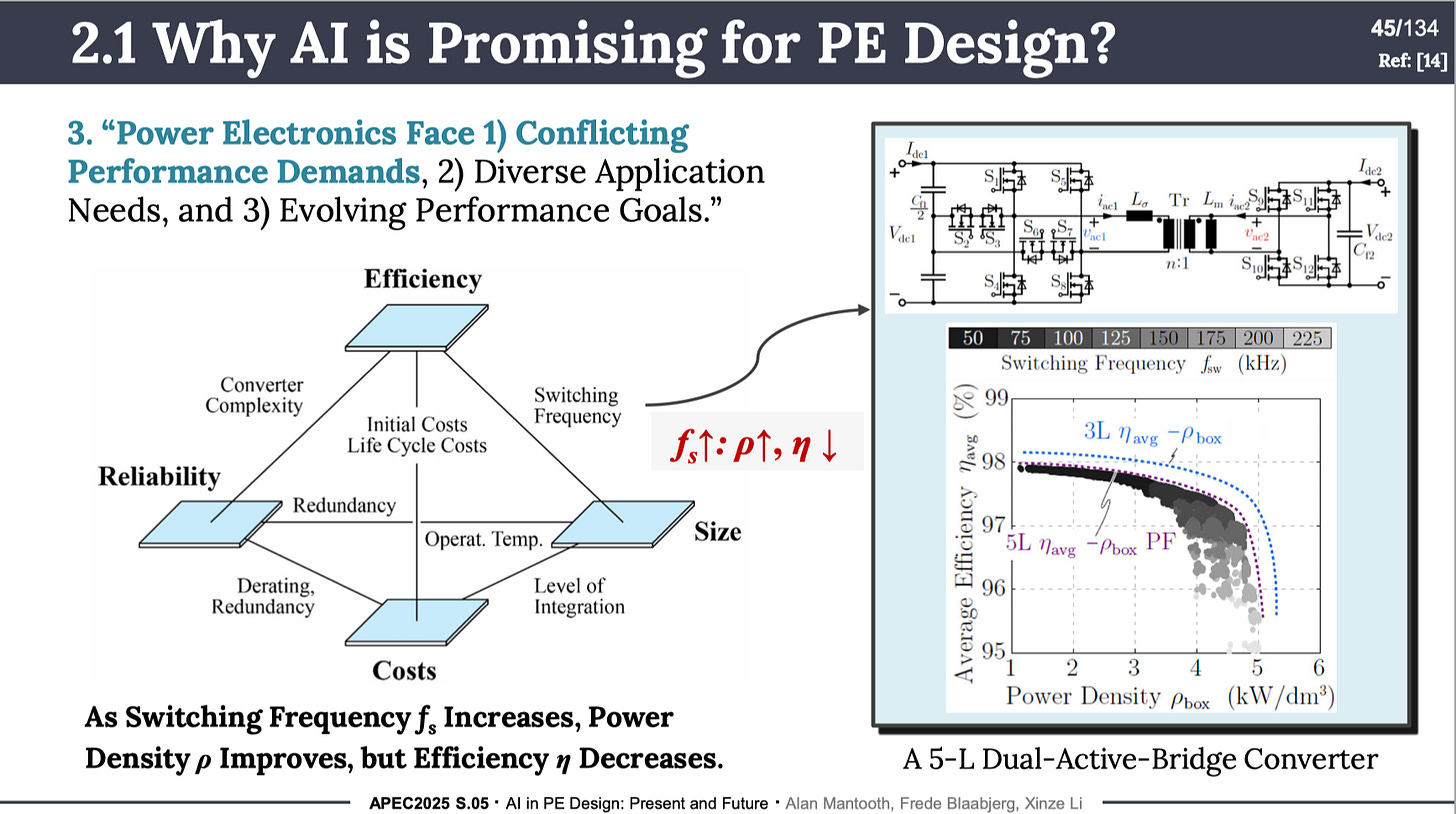

The AI-related articles presented at APEC mainly focused on training models for specific problems, and Sunday's educational seminar [1] is a good example of this.

In this seminar, with over 400 live attendees, the first 90 minutes provided a comprehensive review of countless models developed over the past 20 years that used Type 1 AI. Many people nearly fell asleep. The second part showcased an example of LLM usage, taking a very exploratory and experimental approach but demonstrating a practical case.

The presentations in the industry session also focused on Type 1 models, except for the first presentation, which explained the use of LLMs for tasks related to the BOM [2].

I'm sure that next year, we will see many more presentations using LLMs to solve problems in Power Electronics more quickly—or at least, that's what I hope will happen.

The Vision for Frenetic

Since Frenetic was founded, we have been searching for different ways to solve problems. We started by filing a patent on toroidal magnetics, where we adjusted the material's permeability to create the perfect "toroid." By developing software to design and calculate it, Frenetic was born, initially using standard materials.

We quickly ran into many models that were too imprecise to trust blindly. Even FEM simulation software presents errors of 30-40% when magnetic losses occur in the core. So we thought: If we could gather enough data to train an AI to help us design a magnetic component based mainly on experimental data, it would be the holy grail.

That was when we discovered another major limitation in hardware. Measuring losses only in the magnetic component was very complex. So, garbage IN, garbage OUT.

At that point, we started focusing on models for specific parameters, with DC resistance and Llk being the first. We achieved excellent results with just 500-1000 measurements, which, after filtering, probably amounted to only 200 valid ones. We complemented them with FEM simulations, and by 2021, the first AI models used in commercial Power Electronics products came to light.

A lot has changed since then, and we've found analytical ways to solve problems with greater accuracy. For instance, for LLk, we use Richard's model, which has a 95.5% accuracy according to our lab measurements.

Our goal is 90% accuracy across all models. Right now, our temperature model is at 85%, which is the most reliable indicator of overall precision since it sums all losses and requires a model to estimate them.

Throughout this time, we've learned that, at the end of the day, we want magnetics that does not exceed a certain temperature. That's why we started measuring the thermal resistance of all shapes and incorporating that into our design algorithms.

Okay, but what about LLMs?

This is where I wanted to get. About six months ago, I started having discussions and dedicating time to studying how LLMs could help in Power Electronics, and I realized there are infinite points of contact.

LLMs are excellent interpreters of what we want. This affects interfaces, meaning: Until now, we needed input boxes to differentiate the information users enter into an application. With an LLM, we can do this with a simple sentence, even filtering out typing errors.

Processing images and documents: LLMs are great at document analysis. After years of studying datasheets with advanced techniques, LLMs are now on the verge of surpassing any of those software solutions—and at a much lower cost.

Generating documents and reports: Using traditional software to generate a report can be a long process that also requires maintenance. With an LLM, it's just a two-line prompt.

Many limitations must be acknowledged:

Avoiding LLM hallucinations

Building a different infrastructure

Requiring deep expertise in the subject matter

However, for me, the key to the future of LLMs in Power Electronics will be PRODUCT.

A product that truly helps people who need a power supply will change this industry.

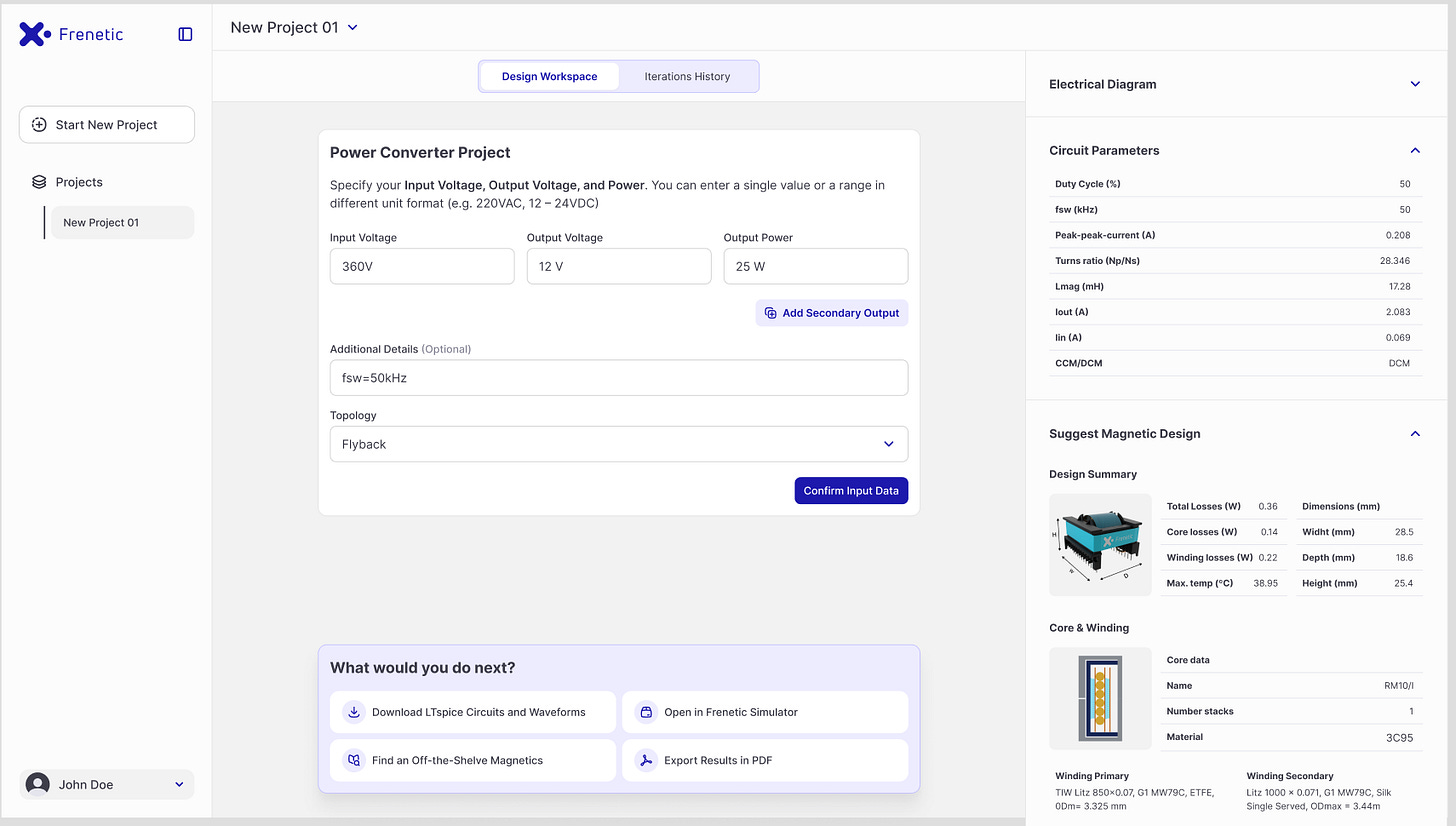

And that’s what we’re working on. If you weren’t one of the 300+ visitors who stopped by our booth to see a live demo of Frenetic AI, here’s a screenshot. And if you want to try it, just click here.

Thanks for reading and the best way to support me is to share this post with your friends 😊.

References

[1] AI in Power Electronics Design: Present and Future, Alan Mantooth, Frede Blaabjerg, Xinze Li, University of Arkansas and Aalborg University

[2] Circuit AI (GenAI Agent for Power Electronics) Bill Of Materials (BOM); Switching Loss Optimization; Capacitor RMS Current Estimation, and MORE, Prasad Enjeti , Vishwam Raval , Mohamed Zeid , and Grant Pitel, Texas A&M University, Magna-Power Inc.