👋 Hello, friends! Dr. Molina here 👨🔧

Welcome to my newsletter! Here, on a weekly basis, I share my personal journey of building a company in the power electronics industry and the exciting new insights I gain about the world of Magnetics.

The Optimal kills the Bello

Every time I think about optimization, I feel a pain in one of my joints that prevents me from moving. It's because beauty is not always optimal. Beauty can be symmetrical, anarchic, or very square, but it's rarely achieved in an optimal manner.

Building a beautiful life is not optimal because it involves going through pain and error. Embracing error as part of the journey toward beauty. When we talk about optimization, we often think of processes designed to reach the best solution as quickly as possible. That's fine if:

You know the path to the best solution.

If the journey is about enjoying, don't make it optimal.

I remember a road route in Cinque Terre (Italy that would never have been chosen by Google Maps; it was beautiful but not the most optimal. Perhaps they lack that option, the beautiful route.

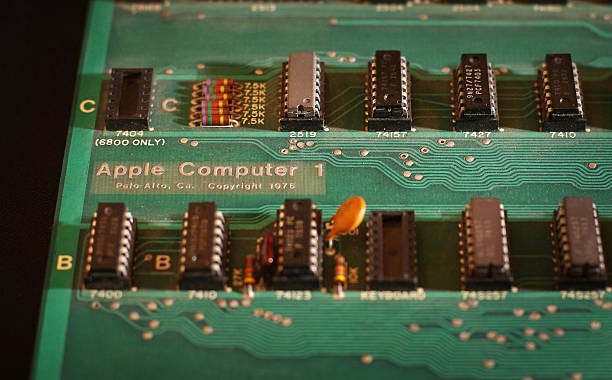

In electronics, you could say that the focus is on optimization until you encounter Steve Jobs, who tells you to make the PCB beautiful because it's part of the culture.

-It's not visible!

-God sees it!- as Kubrick would say.

The work of electronic engineers is to find the “optimal” solution for a specific technical request, however, there are always trade-offs to do, and nobody will be remembered for following the manual of optimization. You need to find your signature and your way of adding Belleza to the design.

Said that having wrong expectations of technologies could make you think that having a planar magnetic would make your design much more beautiful. It’s ok, but I don´t think it will solve your technical problems.

Planar won´t solve your problems

The trend of planar magnetics as the holy grail of magnetics has lasted 30 years. The trend consists of people, usually not magnetic experts, asking for a planar solution to improve their power density. Or teams of engineers, only trying to solve their designs with Planar technologies without considering any other option.

That’s a mistake.

In most cases, the planar solution is not the best, I would say in only 10% of the cases, the planar is the best technical solution for DC/DC magnetics.

Inductors are usually the main discussion, so I will focus on transformers and flybacks directly.

In the Flyback topology, we have done both cases and to be honest, there was only one case I considered interesting.

When the magnetic is integrated into the PCB from the starting moment. When doing the simulation, you already consider a sizeable parasitic capacitance and use the PCB space considering the winding wires.

But in terms of volume, 90% of the cases, you can get a smaller solution and easy to integrate with a concentric magnetic.

For transformers, it depends on the current levels and your mechanical goals. If you consider integrating the magnetic in the PCB, your current levels should be limited to your PCB manufacturer's copper thickness capability.

For very high current designs, this is entirely different. We don´t use PCB; we use cooper layers and the connection to the power module needs some mechanical solution. Additionally, we use a case to improve the heat dissipation, increasing the weight. In this case, a planar solution is likely more compact.

However, once you are not integrated into the PCB, the height can be achieved using Litz or a combination of Litz and Cooper layers.

We saw a good example here in this design completed by Antonio Escudero, in my opinion, one of the best engineers of Infineon.

Integrating Transformer + Inductor

One of the limitations of using a planar transformer is the complexity added in integrating the Leakage inductance as part of the operation. The main reasons are:

The leakage inductance is low and difficult to predict with more than a 70% accuracy

You can include some ferrite layers to increase the leakage like in the Total Component we saw last week.

There is a significant benefit of the planar designs in this regard: the repeatability, which is extremely good.

If you liked it, I encourage you to share this post with your friends or on social media, which will help me to continue writing content for free.

Hey! We are in Production Mode

Why is Frenetic offering you Production?

Well, because we have created a great team of manufacturing and we are already a supplier of parts for Novasonix, Indra or Thales Alenia Space. There are FOUR main reasons to produce with Frenetic:

Our engineers understand your power electronics needs

We are offering BIG discounts for the first orders

We have factories in Europe and the USA

Because you will have access to our Design Technologies

If you want to talk about it, I let you here my calendar to talk about production without any compromise.

See you next week! 🤗