👋 Hello Supergineers! Dr. Molina here! 👨🔧

Welcome to Dr.Molina Newsletter, where I break down Magnetic designs for you every week, in 4 minutes.

In previous editions, I tested Wurth Inductors which you can simulate at Frenetic Online. Today, I will test an inductor of Bourns, concretely the PQ2617BHA-3R3K, an inductor of 3,3uH with a PQ26 core size.

Bourns doesn´t have a design tool, therefore, we have added some of their best inductors to our library. You can simulate them and ask for samples directly in Frenetic Online.

I can say, Welcome Bourns Inductors to Frenetic Online!!

If you are interested in a particular component (or supplier) to be in our Library, just let us know.

You can download the datasheet of PQ2617BHA-3R3K and here you can see a screenshot of the description:

I have simulated the component for a specific AC and DC test and measured it in the lab. Let’s see the results.

DC Test

My colleague Fabio (Thanks mate) put 9,7 A through the inductor, directly connected to a power supply. The simulation shows a temperature of 33ºC and 0,23W and the measurement of the DC resistance is 2,32 mOhm, in the range of the datasheet (well done Bourns).

When we did the test in the lab, the hot spot is at 34ºC, good enough ;). Here you can see the thermal camera screenshot.

The AC test

Once the DC resistance is verified, we moved to the AC test using a Boost type converter. We applied a DC current of 4,15 A with a ripple of 7,7 Apk-pk.

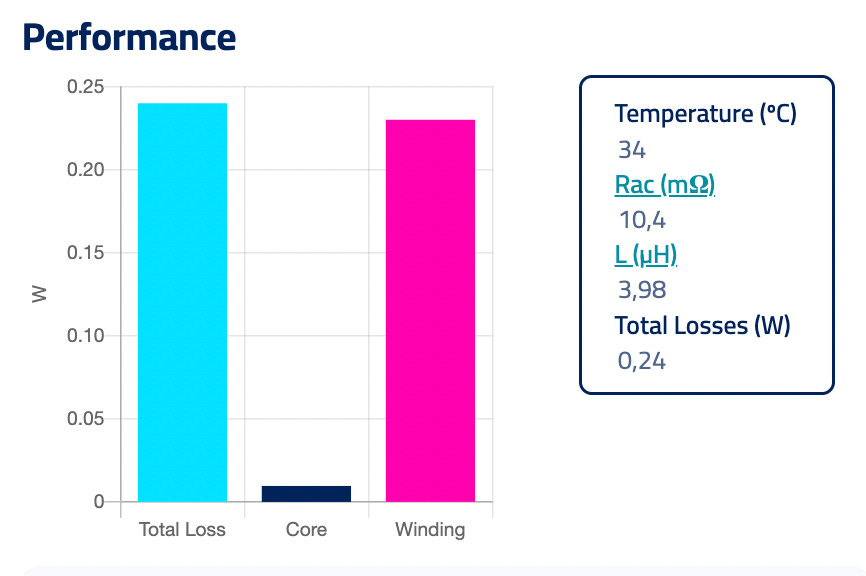

The predicted temperature is 33ºC and 0,23W of losses, most of the losses in the winding.

The following picture is a screenshot of the oscilloscope. There is a lightly resonance in the current, but it should be far from saturation according with the data of the datasheet.

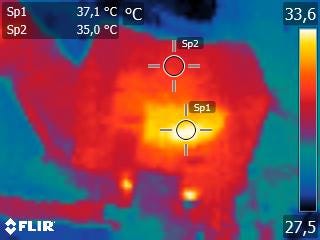

And here we have the temperature screenshot. The hot spot is 37ºC, 4ºC of difference, which is due to the Rac losses estimation. It’s important to note, that the inductor is flying, which means, there isn´t any heat dissipation contact, something it’s not real.

👉 Thank you Fabio for your support in the hardware tests, I owe you a big beer.

Conclusion

The customization of the transformers is very necessary but power inductors are a different story. Companies like Bourns are developing some standard inductors with good performance versus price. However, you need to be sure the component works in your circuit. The best solution is to run a Frenetic simulation and see if you can avoid the complex process of customizing an inductor for production.

Summary of our Vision

🚀 Magnetics are bottle-neck designing Power Supplies

👉 In the process of designing magnetics there are four main areas:

✅ Electrical performance

✅ Mechanical Design (Isolation, connectors, pinout…)

✅ Manufacturing process (It’s feasible? Is tooling needed?

✅ Cost

👉 Most companies focus only on the first area because it’s very complex to build areas 2 and 3.

🤬 The fourth is almost impossible if you are not close to the manufacturers.

❎ Frenetic vision is to support customers in the whole process with a combination of software and service.