39# 🚀 10 kW Payton Design Review & Simulation Challenge

SuperPowers for Electrical Engineers 🦸🏻♂️

👋 Hello Supergineers! Dr. Molina here! 👨🔧

Welcome to Issue 39 of Dr.Molina NL, where I break down Power Electronic designs for you every week, in 4 minutes.

Last week, I received a call from a customer who was interested in the following application note of TI and I started working on it.

It’s a Dual Active Bridge (DAB) Converter for EV charging applications. The topology of DAB is very common when the feature of bidirectionality and isolation is required.

I love the work of TI in this application note because they explain very carefully step by step how to design the power converter. However, they outsourced the transformer, in this case, the design is done by Payton Planar. Let’s review it.

The initial specs of the power converter are:

Input voltage range 700-800-V DC

Output voltage range 380-500-V DC

Output power rating 10-kW maximum

Output current 26-A maximum

Efficiency Peak 98.2% (at 6.6 kW) full load 97.6% (at 10 kW)

PWM switching frequency 100 kHz

Power density >2 kW/L

During the article, they explain how to design the converter, here are their final calculations. I will use this Operating point for designing the equivalent transformer.

Phase shift –0.44 < Ø < 0.44 (rad)

Total Leakage Inductance 35 µH

Turns Ratio 1: 0.625

Load resistance 26 Ω

Input Voltage 800 V

Output voltage 500 V

Input current 12.5 A

Output current 20 A

Output Power 10 kW

CHALLENGE ONLY FOR TRUE ELECTRICAL ENGINEERS

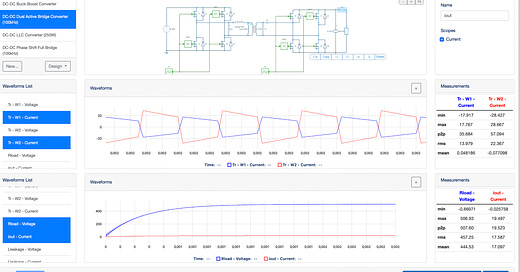

Be brave and curious and try to replicate the simulation here (it’s free) using the previous parameters.

Prize

10 Frenetic T-shirts to the first 10 engineers to answer correctly the question!

The Challenge consists of answering the question below on Linkedin and adding a Tag of me.

Which angle is needed for achieving 10 kW in the simulation?

This challenge should take you 15 min MAXIMUM!

Payton Design Review

The core is selected under the Area-Product method and the considerations:

Current density = 4A/mm2

Flux density = 0.2T (This value is particularly high)

The resulting core selected is an E64/18/50 DMR44 (The equivalent of 3C94 of Ferroxcube) and the number of turns is 22, however, they increased the turns to 24, reducing the flux density 😉.

Losses Calculation

Core Losses are calculated following the table of DMR44. They assume 100ºC and the volumetric losses at that temperature are 300 mW/cm3, resulting 24W in the core.

As you can see, there is no iGSE or any algorithm.

Winding Losses: The DC resistance of a transformer must only depend on the constructive parameters of the winding (length, wire diameter, etc.) plus the environmental condition, such as working temperature.

The AC losses presented two different values 8W and 10W. They presented the AC resistance as a single value at a specific frequency.

I will quote Alfonso to talk about this last calculation.

The AC resistance of the whole transformer at a given frequency must depend on the same parameters and units as the DC resistance, plus the frequency. The problem that exists when presenting one AC resistance per winding, instead of a matrix, as it is common when using methods deriving from Dowell, is that those resistance values are dependent on the frequency and the current circulating in the rest of the windings, producing a hybrid value with units that are not those of resistance, with or without the frequency, tricking the engineer into drawing erroneous conclusions from their losses analysis.

- Alfonso Martinez, CTO of Frenetic

Total Losses according to the article, 50W.

Payton is one of the best companies designing magnetics and their business it’s not to teach you how to design, therefore, it’s normal, that there weren´t clear explanations about their designs.

The article covers the electrical design, which for me represents 20% of the work. If you are working on a similar design, please, remember, that 75% of the work is mechanical and supply chain.

Would you like to learn more about High-Frequency Magnetics and Join the Frenetic Comunity?

We have a Training in High-Frequency Magnetics which is the result of more than 35.000 hours of study, test, and fail, in the whole process of designing a magnetic. We review the electrical design but we also talk about the laboratory process and the supply chain management.

June already started but we can book you a place for the next batch.

Thank you for reading. If you liked it, share it with your friends.

References