👋 Hello friends! Dr. Molina here 👨🔧

Last week, I lost some Italian friends due to my new coffee machine. I’m going to recover their confidence in me with the next picture.

I love pizza with pineapple! Isn´t it great? 🤷♂️ (The unsubscribe is at the bottom of the email)

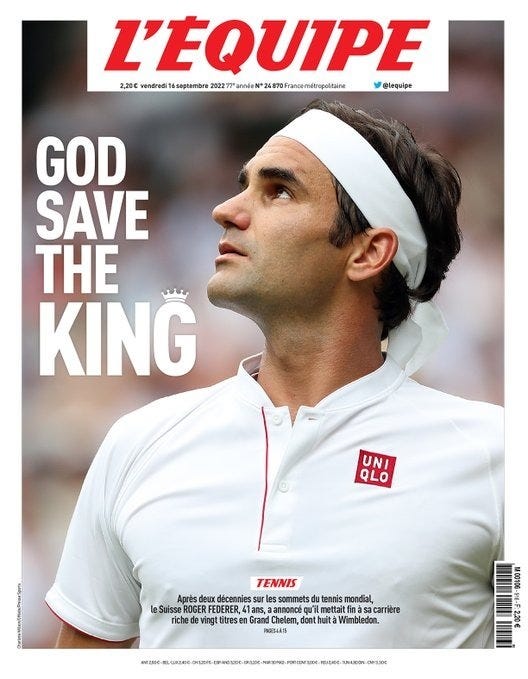

As most of you know, I’m a tennis enthusiastic. This week, the most elegant and iconic player of the history of tennis have announced his retirement.

I found this cover of L’EQUIPE as a good representation.

In the previous edition, I introduced the term Magnetic Power Density (MPD) and we reviewed some figures of merit of the converter’s power density. In this edition we will:

👉 Review the Power density in OBCs

👉 MPD of Automotive DC/DC

👉 Is Excel enough to design Magnetics?

Review the Power Density(PD) in OBCs

The automotive industry is driving the next generation of power conversion, together with servers. But, are the companies aware of the PD of the State of the Art?

Table I shows the current state of the art of PD at different system levels using Liquid cooling. The power density of commercial OBCs is 3,3 kW/l with the goal of increasing up to 4 kW/L in the next 3 years [1].

The DC/DC typical PD is 2 kW/L, much lower than the AC/DC.

The Magnetic PD value is much higher because we are dividing the same power over a much lower volume. However, it will help us to compare different topologies and technologies for the same converter.

The previous values are state of the art, of course, there should be higher values in the market but this is what the reports of the market said [1].

MPD of Automotive DC/DC

The next graph shows some examples of M.P.D. of Frenetic Designs for the automotive industry in 2022 and some other values of Industry converters. The maximum values are from very specific cases with total customization of every part of the BOM.

Thanks again to Florent Liffran (CEO at BrightLoop) for sharing information about his transformer, which has an MPD of 29,3 kW/l in an automotive converter of 1,9 kW. Well done!

In the following table, you can see the details of the designs of the previous graph.

I would like to highlight the design of Unitrode. I have included it because is designed in the ‘90s and it will help to understand. Also, UNITRODE is the company of my dreams 🤗. They did an excellent job for the industry, Bob, Laszlo.. Ray Ridley. The design I have included was designed in the ’90s (8,65 kW/L natural convection was great in the ‘90s)

Having this data in front of us, we can ask.

Which topology provides better results for the MPD?

Which is the relation between P.D. and MPD? Does having a high P.D. ensure a high MPD?

Are PD and MPD follow a parallel evolution with frequency?

What is the relation between MPD and cost?

All these questions are very complex to solve just by one engineer and especially if this engineer is designing using only excel spreadsheets. This is a long effort in terms of time.

Is Excel enough to design Magnetics?

Be honest. When you say, we have our own Magnetic Design software, you are talking about Excel (or Mathcad or Matlab) spreadsheets. I understand you, I have built my own spreadsheets during my Ph.D. and you know what? It worked. But it wasn´t enough.

I’M NOT SAYING DON´T USE EXCEL, I SAY, IT’S NOT ENOUGH

Here, I’m going to write some points where excel is not helping and we need to pay attention.

Spreadsheet understanding: Only you are able to use it. They aren´t company documents.

Maintenance: Every software needs maintenance. You are the only one to know how to do it.

Accuracy: No comments. Excel is a calculation program, the accuracy will depend on the models you include manually.

Materials: You are limited by the core and winding materials you find by yourself, sometimes you can be using obsolete materials.

Difficult to optimize: You are very limited in terms of optimization algorithms.

⚠️ Bad designs Alert

I have seen how you guys are not following a scientific method in Magnetic design. In the medium term, you are losing millions.

Frenetic Online is our software for:

Design your Magnetics with maximum accuracy

Build Samples

Connect with your suppliers and customers

This is what users said about Frenetic Online.

“Best magnetics design platform available today and constantly getting better” – Bob White - President And Chief Engineer -Embedded Power Labs.

“I value especially the freedom to model many different inductors before selecting a single one. The "Suggest Wire" feature - it truly is great!”-

Don Lucas – Senior Power Electronics Engineer at Lucas Consulting Services.

References

[1] J. Yuan, L. Dorn-Gomba, A. D. Callegaro, J. Reimers and A. Emadi, "A Review of Bidirectional On-Board Chargers for Electric Vehicles," in IEEE Access, vol. 9, pp. 51501-51518, 2021, doi: 10.1109/ACCESS.2021.3069448.

Over the conversation with different engineers and companies developing Power Electronics you indeed realize on the fact that there's still trend to make use of owner or company spreed sheets when considering the development of the magnetics training...In several cases, they recognize about levels of accuracies and number of iterations needed along the design stage to reach until the optimal solution.