👋 Hello! Dr. Molina here! 👨🔧

Thank you for reading and welcome to the show of my Newsletter. I’m from a very flat land with hundreds of km of flat ground, it’s called Albacete. If this land were a power converter with a heatsink, the perfect magnetic would be a planar magnetic 😂😂.

As I have announced…I will talk about Planar magnetics!! 🚀.

First of all, big thanks to all of you who have booked a seat in our Training. I’m amazed by the number of subscribers of this Newsletter that will join the Training. We will do our best. Thank you very much.🤗 👏

Madrid - California

I’m back and forth between Madrid and Los Angeles - San Francisco and I love it. I suffer crazy jetlags on the trip to Madrid but I’m learning a lot.

Madrid is a great city with the best social life in the world. The number of high-quality restaurants for affordable costs is amazing. The walks through the city and the international ambient are extraordinary. Additionally, we have three of the greatest schools of Electronics, UPM, Carlos III, and Alcalá. Great talent in a single city. I miss more medium-size industry of electronics.

California is one of my favorites places to live. The weather is very nice, the culture is open and always ready for business. The natural parks are amazing and the density of talent and companies in electronics is crazy. Most semiconductor companies have an office there.

I would love to spend half of my time between these two lands 🚀.

Preliminaries to planarize your converters

Please raise your hand; who have been thinking about using planar technology in their power converters. ✋

I used to receive this question:

Is Frenetic working with Planar magnetics?

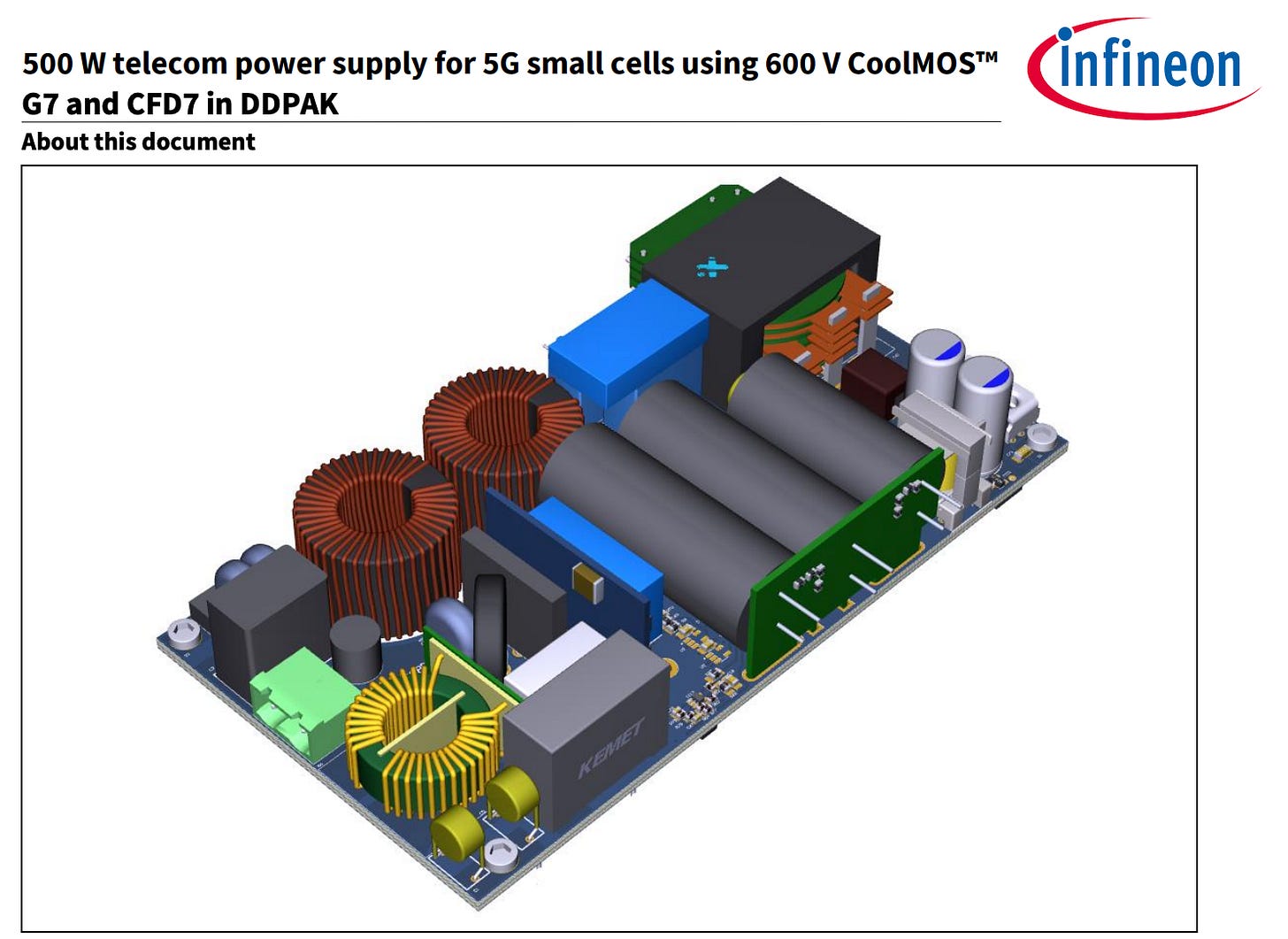

Yes, we work with planar magnetics, primarily as consultants. Actually, one of our planar designs has appeared in APEC on an Infineon App Note 🚀 (We were very excited).

However, in the last APEC 2022, the appearance of planar magnetic hasn’t been massive. If you search the word “planar” in the presentations database, you will find only five results over thousands.

Today, I’m going to talk about planar magnetics from the very basics.

I have used the work of the University of Denmark as a reference in this article [1].

Planar Magnetics Advantages

1) Low profile

2) Good thermal characteristics and high power density

3) Ease of manufacturability and cost reduction

4) Repeatability

5) Modularity

6) Ease of implementation on winding interleaving

7) Integration with other passive components (Capacitors or Switches)

Disadvantages

1) Large footprint

2) Low copper fill factor

3) Limited number of turns

4) High winding capacitance

5) Isolation

Winding Losses

The current critical point in magnetics is the winding losses. The problem with using PCB is the limited area of the layers in classical PCB. Therefore, you can use stamped copper turns to implement high current layers. Manufacturers like Standex and Payton Planar have deep know-how of these technologies for high-power applications.

Losses due to the Air Gap

I have found fascinating the study of the losses due to different positions of the gap. The following picture shows six different configurations of the gap.

The following graph shows the Rac/Rdc losses over frequency for each gap position. As you can see, the center gap is the worst case, when usually this is the best case for wound magnetics.

Planar Sandwich Structure

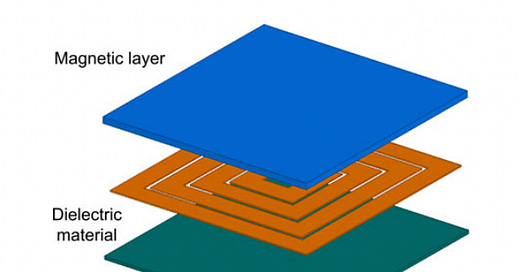

The following picture shows a common structure in an extremely low-profile design. The structure shows two magnetic pieces with the primary and the secondary in the middle, separated by an isolation layer. The window is acting as a gap.

This type of planar magnetic is common in embedded systems or power supplies on-chip.

Planar Example in a Dual Active Bridge

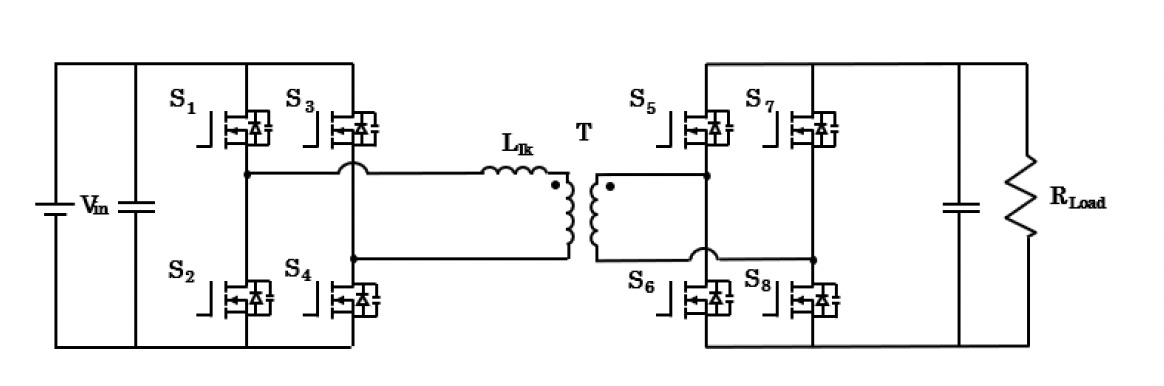

Marcos Luna, one of our specialist on Dual Active Bridge, has created an app note for DAB transformers with experimental results of three different transformers (All of you who has registered in our Training will receive the complete work details).

One of the three cases explained is a planar design. You can see the design, waveforms, and some measurements in the picture. The secondary waveform has a lot of oscillation because of the resonance between transformer parasitics and semiconductor parasitic capacitance. However, the primary voltage and the current shape are pretty clean.

Due to the low Leakage inductance, the external inductance is bigger in this case than in the wound cases. What we would like to discuss in the course is:

In terms of cost, Which is the MOQ to select a planar design instead of a wounded one?

My conclusion

From my personal point of view. Planar designs are a direct solution to reduce suppliers. Integrating the magnetic in the PCB, you avoid the discussions with the winding house for a custom component. The main problem could be the number of iterations of the design and the lack of expertise in each company.

Current tools for predicting losses in Planar magnetics are far from being accurate.

I would say, most flyback converters of less than 100W and less than three outputs (AC/DC adaptors…auxiliary power supplies) could be a good fit for planar magnetics integrating the magnetic in the power PCB with a low risk of iterations.

For kW applications (Ex: OBC of 22 kW) you will need expertise in the design of the converter considering the pararitics impact and the High Frequency losses.

I would love to know your opinion about it!!

[1] Z. Ouyang and M. A. E. Andersen, "Overview of Planar Magnetic Technology—Fundamental Properties," in IEEE Transactions on Power Electronics, vol. 29, no. 9, pp. 4888-4900, Sept. 2014, doi: 10.1109/TPEL.2013.2283263.

Would you like to learn How to Design a Planar Magnetic?

On the 20th of April we will have a Training course:

Click here to get your training at 1.990€

If you acquire this Training, you will have access to our Planar Magnetic Course, once is ready.

This is less than the cost of attending APEC.

That’s all for today. If you have found this newsletter interesting, please, share it with your friends.

Sincerely,

Chema 👋